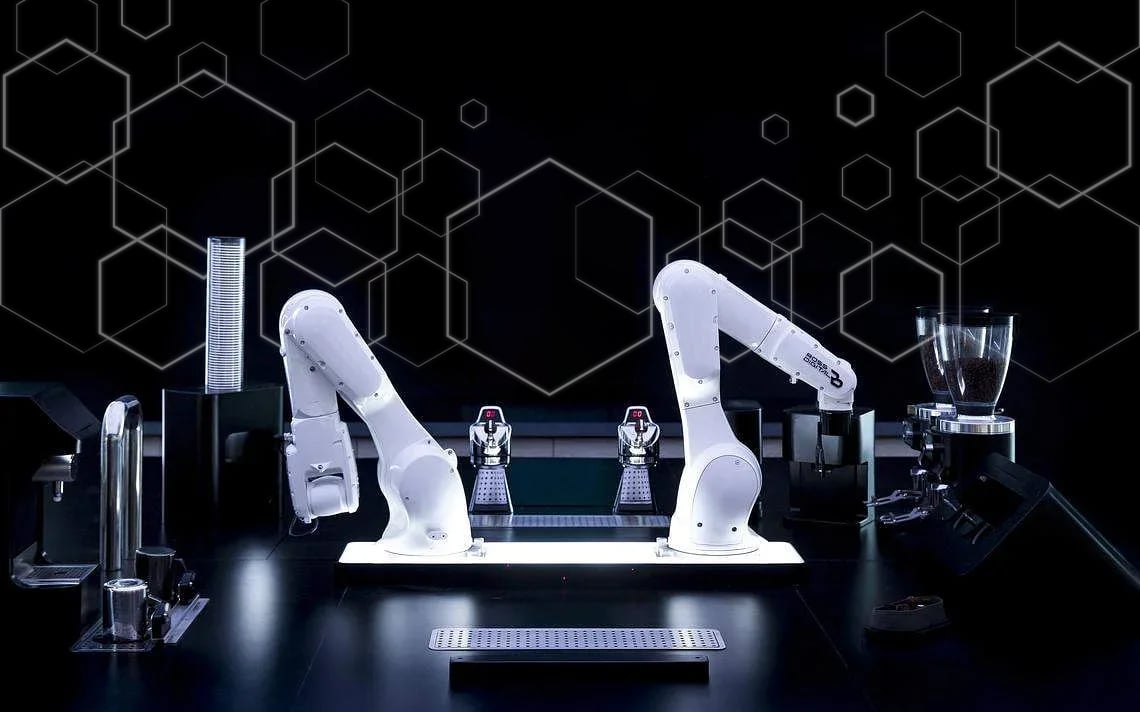

What Are Robotic Arms?

Robotic arms are advanced automation devices designed to replicate the movement and functionality of a human arm. These state-of-the-art robotic automation systems consist of multiple joints, actuators, and end-effectors that enable them to perform complex tasks with high accuracy. Powered by artificial intelligence, machine learning, sensors, and automation software, robotic arms are widely used across multiple sectors, including industrial automation, healthcare, logistics, and food service.

Key Benefits of Robotic Arms in Automated Service Solutions

1. Increased Efficiency and ProductivityRobotic arms can operate continuously without fatigue, significantly improving production rates and service efficiency. Automated solutions equipped with robotic arms enable faster assembly lines, streamlined workflows, and reduced downtime, enhancing overall business performance and automation processes.

2. Precision and ConsistencyUnlike human workers, robotic arms perform tasks with high precision and consistency, eliminating human error. In industries requiring meticulous accuracy, such as electronics manufacturing, industrial robotics, or pharmaceuticals, robotic arms ensure reliable and repeatable processes.

3. Enhanced Safety and Risk ReductionBy taking over hazardous or physically demanding tasks, robotic arms help minimize workplace injuries and improve employee safety. Industries such as construction, chemical handling, and heavy machinery manufacturing benefit from robotic solutions that reduce exposure to risks and improve automated safety protocols.

4. Cost Savings and Operational EfficiencyWhile the initial investment in robotic arms may be high, their long-term benefits outweigh costs. Businesses save on labor expenses, reduce material waste, and optimize workflow efficiency, leading to higher profitability, sustainable operations, and better cost-effective automation strategies.

5. Adaptability and IntegrationModern robotic arms are designed to be adaptable and integrate seamlessly into existing robotic automation systems. Equipped with AI-driven learning capabilities, they can be programmed for various tasks, making them a valuable asset for industries undergoing digital transformation and smart automation.

Applications of Robotic Arms in Automated Services

- Manufacturing & Assembly: Automating tasks such as welding, painting, and packaging for increased precision, speed, and industrial automation.

- Healthcare & Surgery: Assisting in delicate procedures, robotic-assisted rehabilitation, and patient care through robotic medical automation technology.

- Food & Beverage Industry: Preparing, serving, and packaging food items with efficiency, precision, and hygiene compliance through robotic kitchen automation.

- Retail & Customer Service: Assisting with inventory management, automated checkout, robotic customer assistance, and product handling in smart retail automation.

- Logistics & Warehousing: Sorting, packing, and transporting goods to optimize supply chain automation and warehouse robotics.

Challenges and Considerations

Despite their advantages, robotic arms come with challenges such as high implementation costs, maintenance requirements, and the need for skilled professionals to operate and program them. Businesses must also address ethical concerns related to workforce displacement and ensure a balanced approach between automation and human employment. Implementing an effective robotic automation strategy can help mitigate these challenges.

Conclusion

The rise of robotic arms in automated service solutions is reshaping industries by enhancing efficiency, precision, and safety. As technology advances, businesses that embrace robotic automation will gain a competitive edge, unlocking new opportunities for growth and innovation. Investing in robotic arm technology today will pave the way for a smarter, more efficient future.